-

email:

ceo@szsmt.com -

WhatsApp/Tel/WeChat: +86 135 3057 5115

Why is SMT high temperature tape an essential tool in the electronics industry?

Why is SMT high temperature tape an essential tool in the electronics industry?

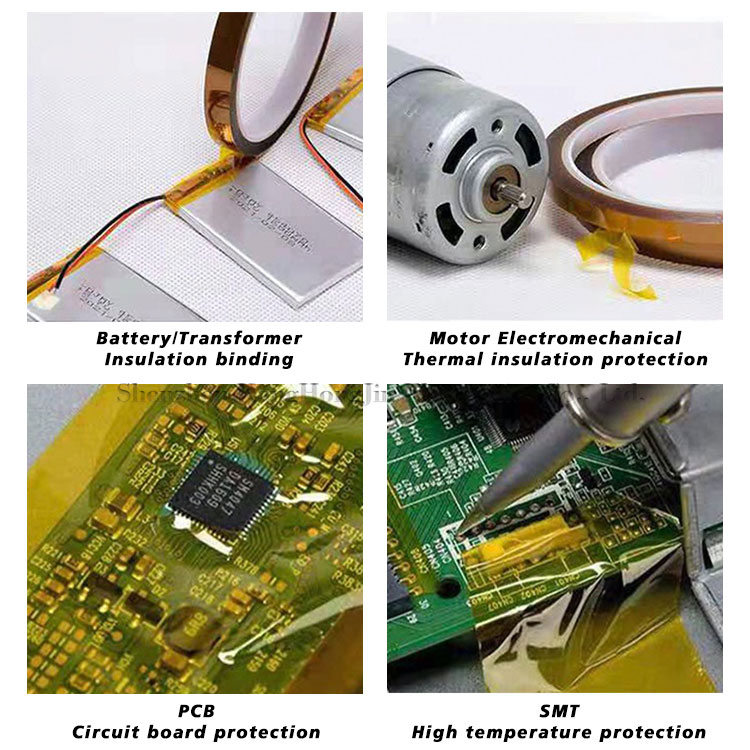

SMT high temperature tape is an essential tool in the electronics industry. It is used to protect delicate components during manufacturing processes such as soldering and reflow.

The tape is made from a specially formulated polyimide material that can withstand high temperatures and harsh chemical environments.

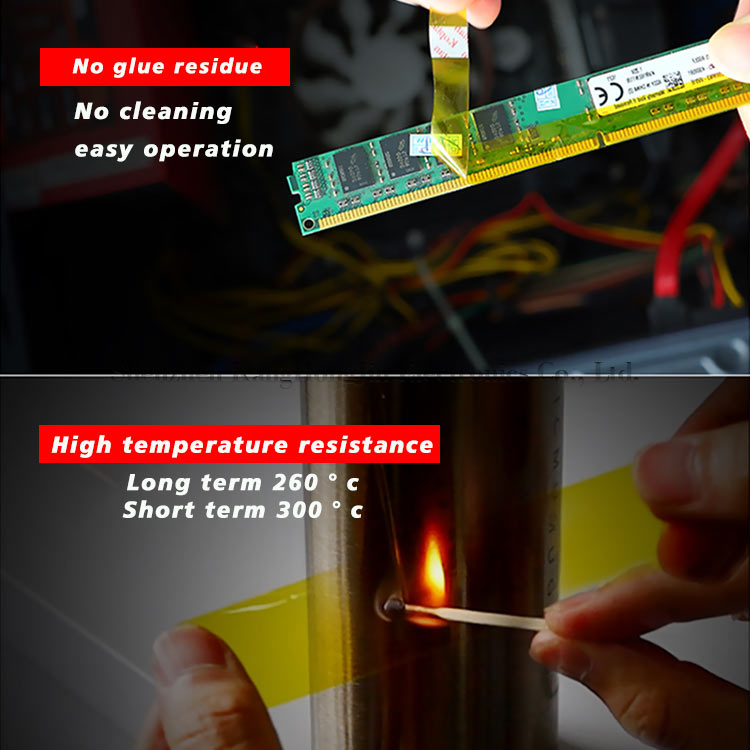

One of the most significant advantages of SMT high temperature tape is its ability to resist heat.

During the soldering process, temperatures can reach up to 260°C. Standard tapes cannot withstand these high temperatures and will melt or leave residue behind, potentially damaging the components.

However, SMT high temperature tape can withstand temperatures up to 350°C and maintain its structural integrity. This makes it an ideal solution for protecting electronic components during manufacturing.

Another benefit of SMT high temperature tape is its ability to resist chemicals. During the manufacturing process, various chemicals are used to clean or etch the circuit board.

These chemicals can damage or weaken standard tapes, but SMT high temperature tape is resistant to most chemicals and can protect the components from harm.

In addition to its protective qualities, SMT high temperature tape is easy to apply and remove. Its strong adhesion ensures that it stays in place during assembly, but it can also be easily removed without leaving residue behind.

Overall, SMT high temperature tape is an essential tool for the electronics industry. It provides reliable protection to sensitive components during the manufacturing process, ensuring that they remain intact and fully functional. Its high-temperature resistance, chemical resistance, and ease of use make it an ideal choice for any electronics manufacturer.

Kang Hongjin has over 20 years of production experience, and always controls the raw materials, production process, testing and inspection, quality tracking and tracing, quality management system and other aspects to ensure product quality meets standards. Always pursuing higher quality requirements, Kang Hongjin customizes various products to meet customer needs, and has launched new product solutions to eliminate pollution during the feeding process, among other initiatives.

![loading... [65x60]](https://shopsource.singoo.cc/1027/general/HGxDHxnn7x7dADWb.png?x-oss-process=image/resize)