-

email:

ceo@szsmt.com -

WhatsApp/Tel/WeChat: +86 135 3057 5115

SMT Steel Mesh Wiping Paper - Difference in Wiping Effect

SMT Steel Mesh Wiping Paper - Difference in Wiping Effect

SMT Production Line - SMT Stencil Cleaning

SMT Stencil Cleaning Wiper - Wipe Difference Effect

.

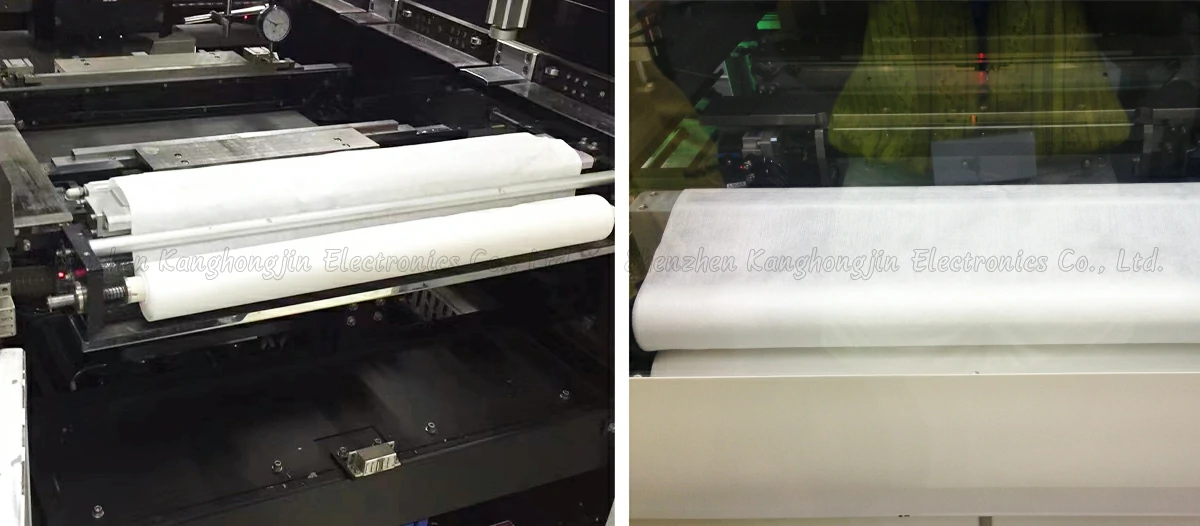

SMT steel mesh wiping paper, also known as SMT automatic wiping paper, SMT roller wiping paper, SMT dust-free roll paper, SMT wiping roll paper, etc.

But the difference between wiping papers is huge? So what are the factors that affect the effect of wiping paper?

Detailed introduction to the material of SMT steel mesh wiping paper and its influence on the wiping effect, choose the appropriate wiping paper.

1. Material

Using natural wood pulp and polyester fiber as raw materials, it is processed by a unique water spunlace method to form a unique wood pulp/polyester double-layer structure.

.

2. Performance

Strong and durable, with high water and oil absorption, soft, dust-free, anti-static properties.

The material is soft and does not produce any scratches on the surface of the cleaned object or damage the surface of the object.

Can be used with cleaning solution.

Super strong liquid absorption capacity, more than four times faster than ordinary cotton rags.

Highly efficient removal of water stains and oil stains, without the use of any chemical adhesives.

Because it is produced in a clean room, impurities are avoided in the wiping paper, which can reduce the occurrence of printing defects caused by impurities carried by the steel mesh during the printing process.

It can be used with anti-static packaging to meet the strict anti-static requirements for electronic products.

.

3. Types

Plain paper and grid paper, imported PP material

.

4. Unit weight

56, 60g, 65g, 68 g/m2 Thickness 0.3-0.35 mm Width 20-800cm

.

5. Lined tube

Paper tube and PVC plastic tube. The tubes used in different printing machine models have slots or no slots at both ends.

6. Application

It is used for cleaning high-standard surfaces. It is a special wiping paper for SMT printing of circuit boards in the electronics industry. It can effectively remove excess solder paste, red glue, etc. attached to the steel mesh and circuit boards of the printing machine, keep the electronic circuit boards spotless, thereby greatly reducing the scrap rate and greatly improving production efficiency and product quality.

.

It can be used for all fully automatic printing machines such as MPM, DEK, KME, YAMAHA, MINAMI, JUKI, EKRA, PANASERT, FUJI, SANYO, etc.

.

7. Specifications

The width and length of the dust-free paper and the diameter and length of the inner lining tube are all subject to the actual printed product size and the printing machine

.

For SMT steel mesh wiping paper, in addition to the above five factors, the main factor affecting the bulkiness and thickness indicators is the temperature of the oven. Within the allowable range of the production process, if the temperature is higher, the hot melt bonding will be better, and the bulkiness and thickness will be higher.

>

Accept OEM/ODM

Dear customer, we make a lot of tapes in different colors and size, please send inquiry to us with your request tape size and color, we could show you our finished products and tape specification according to your usage.

-

KangHongJing is a professional production and sales factory. I hope it can help you. If you want to know more about SMT assembly information, you can follow the updates of KangHongJing.

WhatsApp/Tel/WeChat: +86 135 3057 5115 E-mail: marketing@szsmt.com

Shenzhen Kanghongjin Electronics Co., Ltd.

![loading... [65x60]](https://shopsource.singoo.cc/1027/general/HGxDHxnn7x7dADWb.png?x-oss-process=image/resize)